C3 - Closed Carbon Cycle for mixed plastic waste

Ingénierie et Architecture

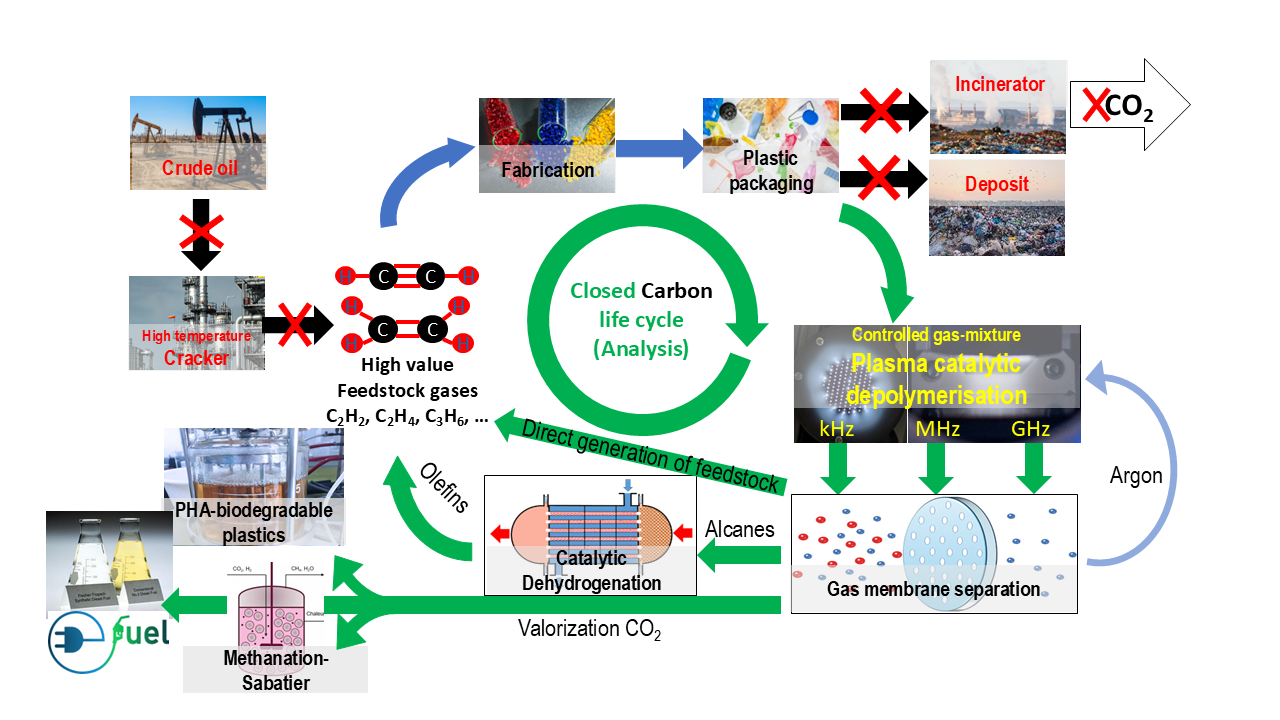

Large amounts of plastic waste resulting from a non-circular plastic life cycle, generated from fossil crude oil, represent one of the major environmental issues today, polluting the environment in controlled or uncontrolled waste deposits or generating CO2 in incinerators. In spite of common efforts to improve waste collection, according to the Federal Office of Environment, the recycled fraction of today’s plastic waste generation remains at 50%. Various recycling processes for specific polymers are presently under development (various start-ups have been founded thereupon), but require highly selected materials as input, which is the common major issue of nowadays plastic recycling. All newly proposed processes rely on high quality waste separation, which is mostly done manually to achieve the required purity levels. Thus, mixed plastic waste remains the major issue. Non recycled plastic waste ends usually up in the incinerators (in Switzerland) and generates CO2 emission into the atmosphere or on controlled (or uncontrolled, 3rd world) deposits, polluting the environment.

Even though Switzerland occupies a leading place in recycling household waste, just about half of plastic waste is recycled, while the other half goes into incinerators. Plastic is a material which due to its light weight and versatility cannot easily be replaced in most applications, neither in industry, packaging, domestic, construction, mobility, etc. Thus, Switzerland has made a clear commitment to integrate the plastic material into the emerging circular economy.

The figure 1 illustrates the closed carbon cycle (C3) of plastic waste replacing crude oil as the prevailing carbon source by plastic waste while eliminating the release of CO2 into the atmosphere.

The proposed development requires both the development of the systems (reactors, machines, integration) and process development (analyzing parameter space). In accordance with this twofold requirement, the consortium is composed of four schools of engineering, with technical and scientific skills for system development and process knowhow, to evaluate the performance in terms of environmental impact and LCA. Therefore, knowhow from the experimental side as well as the theoretical basis are combined such that reactor development and the experimental characterization of the developed systems can be well accompanied by simulation and modelling, leading to a good understanding of the systems and allowing to reduce the number of iterations to reach the best performance. While the plasma expertise of two groups (HEI-Vs and HEIG-Vd) will concentrate on the reactor development, the chemical know-how in HEIA-Fr and HEPIA will lead to the development of the alkane/alkene catalytic upgrade. Gas separation and system integration will be carried out by combining the knowhow in thermal processing and fluid dynamics of industrial scale equipment at HEI-Vs with the mechanical engineering experience from HEPIA.