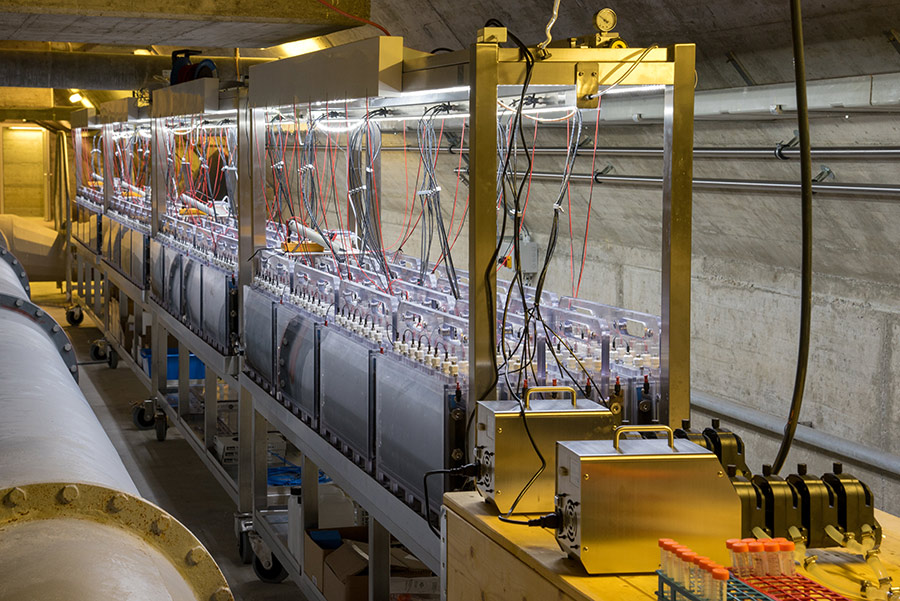

Stretched 1000-L microbial fuel cell

Ingénierie et Architecture

Wastewater treatment consumes 1–2% of electricity in industrialized countries. This notable energy consumption is due to highly powered air pumps that saturate influent wastewater with air-oxygen. This procedure ensures efficient microbial respiration and accelerates waste digestion. The process consumes ~70% of electricity needed to operate a municipal wastewater treatment plat (WWTP). Conversely, there is considerable energy contained in wastewater (1.9 kWh/m3). This is in most WWTPs more energy than needed for treatment (0.3–2.1 kWh/m3).

Bioelectric wastewater treatment potentially will invert today’s power consumption into tomorrow’s energy generation. The microbial fuel cell (MFC) based purification process is performed with electrogenic and other anaerobic microorganisms. Electrogenic microbes respire over anodes and generate electricity while digesting waste. The power recoveries so far achieved were between 0.015 and 0.024 kWh/m3. The recoverable energy for a WWTP of 100′000 people equivalents corresponds to the electricity consumption of 42–67 households (5200 kWh/y per home). Even higher are energy savings due to much reduced aeration, what corresponds to another 100 household equivalents when based on a 75% reduced energy consumption with dual chambered MFCs and compared to lagoon aeration.

The use of MFCs as power generators is particularly challenging when wastewater becomes almost clean. There, power generation drops due to fuel starvation effects and mass transfer limitations and removing residual COD is sluggish.

Another useful purification process in wastewater MFCs is ammonium transformation into nitrite and nitrate, which is subsequently reduced into nitrogen. This redox process is initially electron producing and then consuming and not adding to the power generation faculty of wastewater MFCs. Beside this, ammonia is eventually recoverable from the cathode as it migrates through the cation exchange membrane. However, ammonia migration is not a major process and competes with other cations such as: H+, Na+, K+, Mg2+ and Ca2+.

The above discussed capacity of MFCs to purify wastewater was shown for litre scale reactors. Large-scale microbial fuel cells with energy harvesting electronics, more than 100 L, are not widely documented. With larger setups mixed performance results are reported and most problematic were power generation problems after several weeks of operation. This is at an early stage and a serious problem for the prospect of MFC driven wastewater treatment, as it should work for decades. There are many processes in a MFC that require control. If one of them is deteriorating, a rapid resolution is needed to perform the purification process over a prolonged time. Wastewater is not an all convenient substrate in contrast to others that would lower the risk of MFC failure. These are: synthetic mixtures, urine, and wastewater from food processing.

Another complication with stacked MFCs for enhanced performance, are voltage reversals. They are caused often by fuel starvation, other reasons are high stack currents and internal resistances rise resulting in voltage reversals of individual MFC units in the stack and failure from microbial stress. Another reason were corrosive effects by damaged electrodes destroying biofilms. In addition, small changes in individual MFC units result in imbalances among MFC units and reversals occur just as voltage sweeps for this reason.

Amid all technical inconveniences the concept is attractive for treating municipal wastewater, as it is a cheap and most abundant feed stock. To achieve process robustness, considerable scientific challenges remain, in generating efficiently electricity from microbes. The working potential of an MFC is 0.5 V under ideal conditions and a serial stack of four MFCs generates 2.0 V. This potential is high enough to transform obtained power into useful electricity. The difficulty with electricity generation in wastewater treatment-MFCs is power decline due to COD removal as wastewater becomes purified. Therefore, low voltages and currents need to be considered too. The question is how to choose an appropriate design for scale up MFCs to ensure its function at all conditions, structural stability and best performance.

Structural stability of larger microbial fuel cells was studied recently with the construction of three 168-L microbial electrolysis cells used equally as MFCs. They consisted of a 2.4 m long common anode chamber and an external steel frame for structure reinforcement. These reactors remained functional for at least two years in WWTPs. The building of bioelectric systems reactors longer than 2.4 m were challenging for constructors. This because longer than 2.4 m stiff polymer plates were not available and automatized cutting tools were neither laid out for larger plates and manual work would be needed enhancing construction cost. To solve this problem, multiple smaller reactors could be built by more automatized construction steps resulting in series of hyphenated small reactors. However, WWTPs deals with large volumes and bigger sized units decrease the numbers for needed fittings, cables, tubes and sensors.

In this work a 1000-L MFC was planned by computer aided design (CAD), constructed, and operated. The 12 m long MFC-reactor was installed in an underground gallery of a municipal WWTP (Chˆateauneuf, Switzerland). The temperature of the MFC-reactor was roughly identical to the one in aerated lagoons just above the 1000-L MFC. Examined parameters were chemical oxygen demand (COD), power, energy efficiency (EE), Coulomb efficiency (CE), pH, internal resistances, voltage reversals, nitrification, denitrification, desulfurisation, phosphate reduction and micropollutant removal. Energy generation was optimized by maximum power point tracking (MPPT) and electricity stored on lithium batteries. 64 Anodic microbiomes were sequenced for structure and metabolic mapping using 16S rRNA method.

To read the full project, please consult this scientific publication: Stretched 1000-L microbial fuel cell.