The development and industrialization of microtechnology products requires a broad knowledge base and a wide range of multidisciplinary skills. With the MSE in Microtechnology, you will be better equipped to meet the many challenges of today, such as the transition to the digital factory.

National profile description (.pdf)

Concept

The Master of Science in Engineering (MSE) in Microengineering is a logical continuation of the Bachelor in Microengineering. It is also an opportunity for holders of other bachelor's degrees to reorient themselves and discover new horizons.

The theoretical and applied modules of the MSE in Microengineering will reinforce the skills obtained in the course of the bachelor's degree, particularly in the areas of multidisciplinarity, product industrialisation and behavioural qualities.

More specifically, you will acquire in-depth knowledge and skills in the following areas:

- Advanced design methodologies, including functional product analysis, as well as ergonomics and reliability aspects

- Development of advanced and intelligent sensors

- Advanced manufacturing processes specific to microtechnology product

- Inspection and quality control, using automated solutions based on, for example, machine vision

Target group

Specific skills are required to apply for this profile. Students with an above-average degree in one of the following Bachelor's programs generally meet these admission requirements:

- BSc in Microtechnology

The assessment of initial qualifications is part of the University’s admission procedure. Students who do not hold one of the above-mentioned Bachelor's degrees will be assessed individually for suitability by the relevant University.

Professional profile

Microtechnology is clearly a flagship of Swiss industry. For example, in Western Switzerland, the watchmaking and microtechnology sectors employed close to 60,000 people in 2019. Microtechnology, i.e., all techniques aimed at designing, manipulating and manufacturing miniature systems, is at the crossroads of micromechanics, electronics, IT, optics and materials science. As such it requires an extensive array of knowledge and skills. Thanks to the MSE in Microengineering, your multidisciplinary knowledge will be reinforced, as will your skills in the industrialization of products and your behavioural skills. You will thus be ready to take up the challenge of the transition to the digital factory, and to carry out a highly complex applied research and development project with a high density of technological integration.

Skills to be developed

Holders of a Master's degree in Microtechnology will be capable of developing and designing miniature parts or devices for various industries such as watchmaking or MedTech, as well as the production resources and instrumentation. In particular, holders of this degree will be capable of developing microtechnical products with high added value, with a focus on integration, reliability, ergonomics, quality and environmental impact.

They will also have a deep knowledge of microtechnical manufacturing and micromachining processes (conventional micromachining, laser micromachining, electroerosion, micro-nanotechnologies). They will be able to identify the most appropriate microtechnical manufacturing process for a specific application and integrate it from the design phase onward.

Their general knowledge in fields as diverse as general mechanics, information and communication technologies, electronics, physics, optics and materials science allows them to have a complete and detailed vision of an interdisciplinary project. Within a research or development team, they will be the key contact, able to dialogue with specialists in the various engineering fields and to analyse and understand the mechanical, electronic and IT issues involved in a project.

Their multiple, interdisciplinary and behavioural skills enable them to imagine, create and develop innovative solutions in the field of watchmaking, advanced sensors, quality control, biomedical devices, production means, robotics and automation. Moreover, their open, innovative and creative spirit makes them key players in meeting the current challenges facing the world of microtechnology, such as the transition to the digital factory, by contributing their specific knowledge and skills in industrial visioning as well as in automated and robotic systems.

Moreover, this interdisciplinarity, the ability to carry out complex projects, as well as the required behavioural skills make them credible candidates for more senior positions as project managers, product managers or team managers.

Specialisations

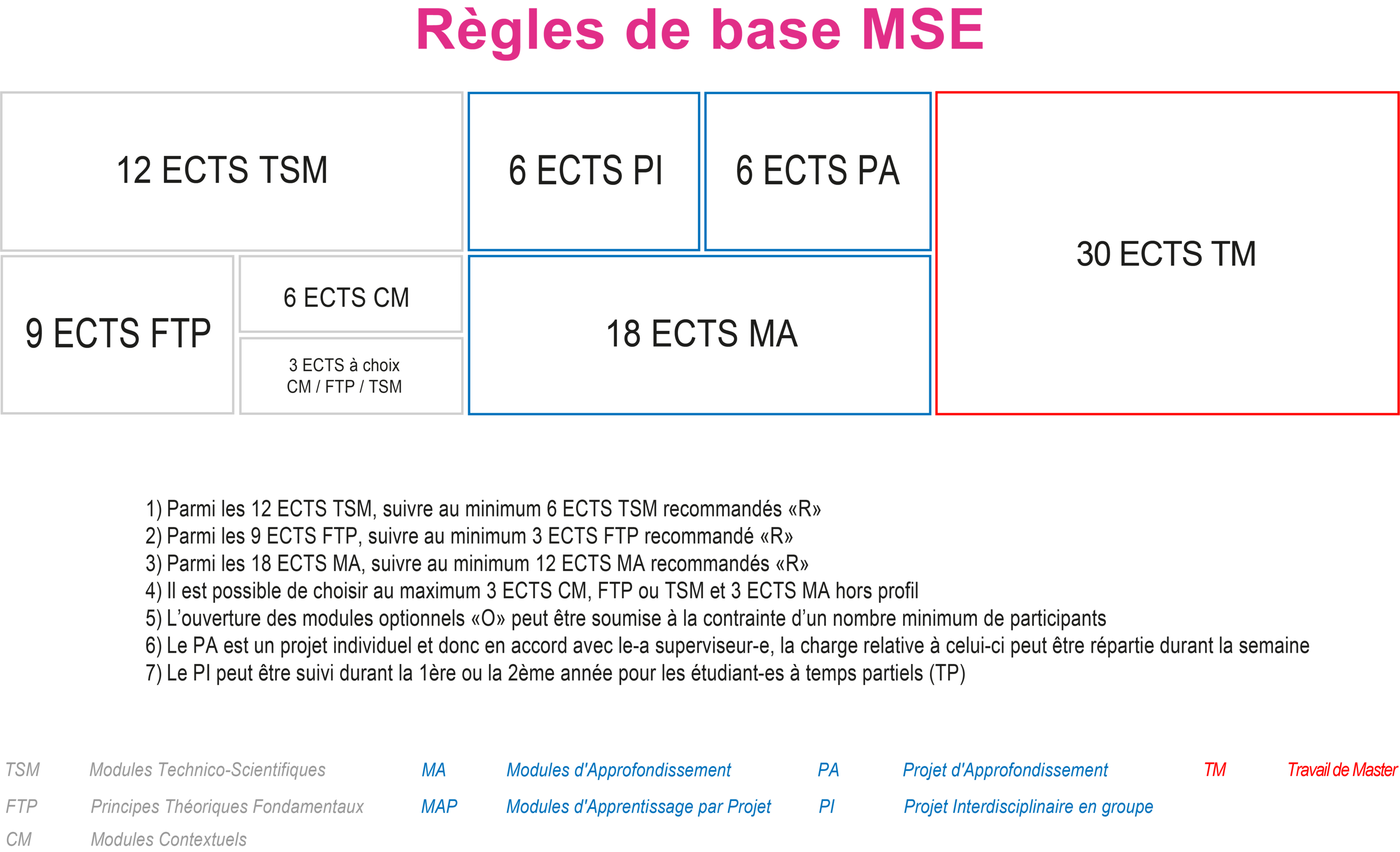

Through the in-depth modules, projects and the Master's thesis (60 ECTS), you will also have the opportunity to deepen more specific skills in the "business" orientations of your choice. For example:

- Biomedical engineering

- Watchmaking engineering

- Development of microsystems

- Microtechnology production and manufacturing

Contact

Yves Salvadé

Head of the profile Mic (major)

HES-SO Master

Av. de Provence 6

1007 Lausanne

T + 41 58 900 00 00

mse(at)hes-so.ch